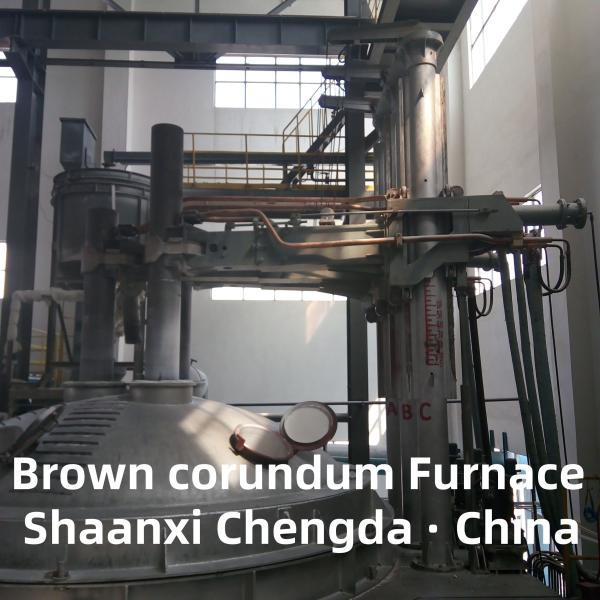

Brown corundum Furnace

Corundum smelting furnace overview:

Corundum is generally made of industrial alumina or bauxite after

sintering or electric melting. When industrial alumina is

electromelted, white corundum is obtained, and its Al2O3 content is

greater than 98.5%; When bauxite is used as raw material, common

corundum is obtained, and its Al2O3 content is 91~93%, and after

treatment, the Al2O3 content is greater than 97%. When iron filings

are added, brown corundum can be produced; When zircon or zirconia

is added, zircon corundum is obtained. That is to say, corundum can

be divided into sintered corundum and fused corundum two major

varieties, and can be divided into white corundum, brown corundum,

zirconium corundum, black corundum, chrome corundum and so on.

White corundum can also be divided into ordinary fused corundum and

low porosity or dense fused corundum. In amorphous refractories,

the use of white corundum and brown corundum as refractory

aggregate and powder has been more and more applied, and remarkable

results have been achieved.

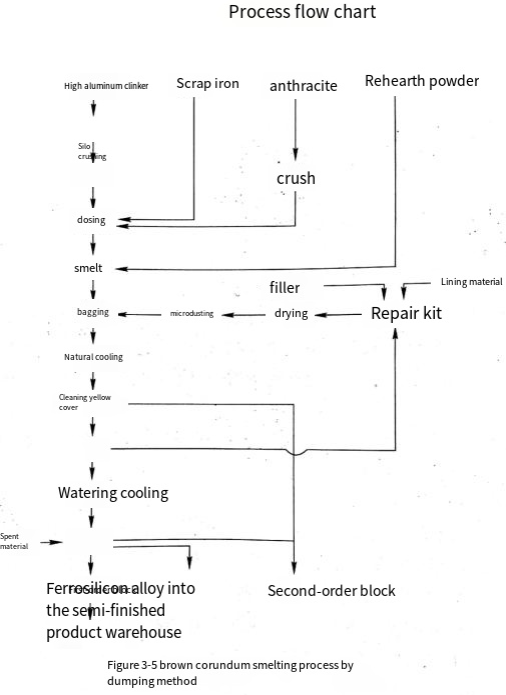

Brown corundum melting furnace process overview:

Equipment Overview:

1. The furnace cover is fixed, and the furnace cover is provided

with 3 feeding ports, observation devices, dust removal ports and

electrode holes. ;

2. Each phase uses a large section of internal water-cooled cable,

compensator, wall through copper pipe, copper pipe conductive cross

arm (trolley lift type) to form a space triangle arrangement of

energy-saving short network. Three-phase impedance unbalance ≤4.5%.

Water-cooled cable and water-cooled copper pipe section current

carrying ≤4.5A/m㎡; The current carrying capacity of the copper bar

section of the short network is less than 1.5A/m㎡.

3. Electrode lifting automatic regulator adopts full hydraulic

proportional valve control automatic lifting regulator. The

electrode lifting can be operated automatically and manually, and

the electrode response time is less than 0.25S. Arc current setting

range: 25%-130%, electrode response time: 0.15S.

4. The furnace body tilting, electrode lifting, electrode holding

brake adopts hydraulic transmission, integrated block hydraulic

valve;

5. The electrode holder adopts copper forging structure, stainless

steel belt type disc spring clamping, hydraulic release, reliable

use, long life.

6. The electrode automatic lifting regulator is controlled by

Siemens S7PLC.

7. The electric furnace transformer adopts low-loss energy-saving

transformer, which can be overloaded by 20% for a long time,

on-load electric voltage regulation, strong oil-water cooling,

transformer primary voltage 10KV, secondary voltage 170-380V.

On-load electric voltage regulation, top out line mode, and

equipped with perfect oil temperature and gas protection device.

8. The high voltage electrical control adopts KYN28 new switchgear,

equipped with a special microcomputer protection device for

electric furnace transformation, with a complete range of voltage,

current, power and electrical measurement and relay protection,

zinc oxide arrester to absorb operating overvoltage, and a simple

rectifying power supply for switching.

9. The cooling water system has pressure and water temperature

monitoring, sound and light alarm. In order to prevent power

failure, the user needs to set up a high water tank.

10. Electric furnace parameters to implement industrial computer

monitoring and management. Advanced and perfect upper computer, the

central centralized control system to achieve the integration of

the production line, intelligent, control, warning, protection

system, to ensure the safe and reliable operation of the production

line, can provide the possibility for the user's data management

network (can be combined with the network communication module,

through the mobile phone remote monitoring of the electric furnace

operating status).