Shaanxi CHENGDA Industry Furnace MAKE Co., Ltd.

Shaanxi Chengda Industrial Furnace Manufacturing Co., Ltd.

is a high-tech enterprise specialized in the research, design, and

manufacturing of various industrial furnaces, including AC and DC

steelmaking electric arc furnaces, ladle refining furnaces,

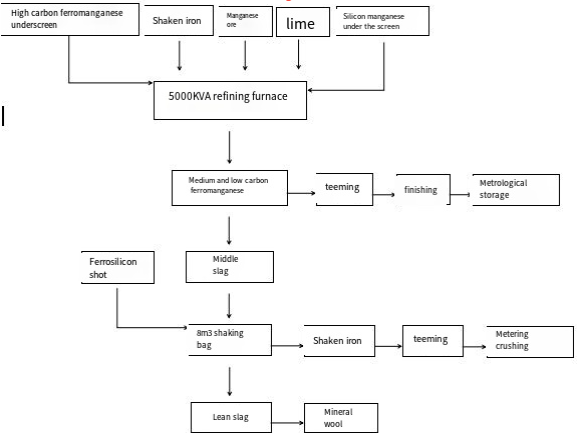

ferroalloy ore thermal furnaces, ferroalloy refining furnaces,

electric slag remelting furnaces, non-standard metallurgical

equipment, heat treatment equipment, and various related

environmental protection dust removal equipment. The company's

product design and manufacturing capabilities have reached 100 tons

for electric arc furnaces, 160 tons for ladle refining furnaces,

and a capacity range of 3600KVA to 35000KVA for ore thermal

furnaces. In accordance with national industrial policies, we have

designed high and low voltage compensation systems, dust removal

systems, ferroalloy DC furnaces, and new energy equipment suitable

for the actual operation of the equipment. For inquiries, please

contact Mr. Du at 13991381852 or Mr. Chen

13709182307.