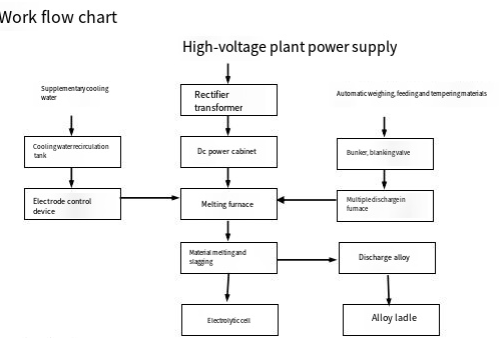

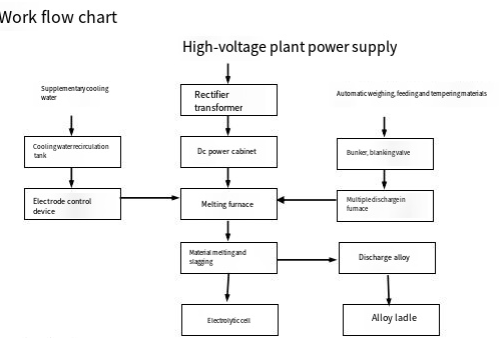

Pulverized coal ash

Equipment use:

Mainly used for the treatment of fly ash, the utilization rate of

traditional arc heating method is often less than 80%, so the

furnace adopts high pressure plasma arc direct breakdown to

pretreat it, greatly improve the efficiency of plasma arc, and

provide molten materials for the subsequent electrolytic process.

Advantages: The process of direct melting of breakdown materials by

high temperature plasma arc in DC furnace meets the appropriate

conditions for direct ion breakdown melting.

The process is simple and has high efficiency. It is a pretreatment

method for large quantities of molten ash reaction.

Equipment technical features:

The plasma furnace melting technology features efficient recovery

of precious metals, so that the recovery of precious metals greatly

improved, the DC electric furnace has the following advantages:

1) The temperature of the electrode center of the DC electric

furnace is as high as 3000-5000C, and the heat is concentrated, and

continuous smelting is more suitable for rapid and large amount of

fly ash smelting.

2) The DC electric furnace has a low flicker effect and noise,

which is very beneficial to the power grid and the operator, and

its flicker effect is only 50% to 70% of the AC electric furnace,

and the noise during submerged arc operation is more than 20dB

lower than that of the AC electric furnace. The natural power

factor is high, and the power factor can reach 0.92~0.94 without

compensation.

3) The power consumption of DC electric furnace is 10% ~ 15% lower

than that of AC electric arc furnace, the electrode consumption is

40% ~ 60% of AC furnace, and the production capacity is increased

by ~ 10% compared with AC electric furnace.

4) Because the operating temperature of the electric furnace is

higher than that of the same type of electric furnace, the overall

structure is consistent with that of the same type of foreign

furnace. The fixed tube type water cooled furnace cover structure

provides an effective gas collection and sealing device for

smelting operation and gas treatment.

5) The whole furnace body adopts the separation method of slag

liquid and precious metal materials, and the front of the furnace

body is provided with a horizontal slag outlet, and the furnace

body is fixed.

6) Adopt the overall multi-touch bottom electrode mode of the

furnace bottom, which can effectively solve the arc deflection

phenomenon of the DC furnace. The furnace bottom is equipped with a

temperature measuring device to detect the lining of the furnace

bottom in real time.

7) Set up two hanging type eye plugging machines to open and plug

the eyes of the slag mouth and iron mouth to maintain the

protective atmosphere in the furnace.

8) Integrated rectifier power supply adopts three-phase full bridge

rectifier device, the AC power supply is rectified into a stable

and reliable DC power supply, which can adjust a wide range of

voltage and is suitable for a variety of material processes. The

rectifier device is cooled by independent closed cooling equipment,

which is safe and reliable.

9) The electrode lifting control adopts Siemens programmable

controller, the actuator adopts German Parker proportional valve to

control the hydraulic cylinder lifting mode, and the voltage and

current double closed-loop control is implemented. The low-voltage

electric appliance uses Schneider components to effectively ensure

the reliability and advanced nature of the equipment.

10) Advanced DCS computer operating system, real-time operation and

operation management of the operation process and operating

parameters.

Equipment structure description:

1.Furnace body

The furnace body is divided into two parts: the upper shell and the

lower shell.

2. Furnace cover

The furnace cover is cooled by tubular water

3. Electrode lifting device and electrode cross arm

The electrode lifting device consists of an electrode cross arm and

a column

4. Furnace tilting platform

The tilting platform of the furnace body is an integral welded

structural part

5. Short-net system

The short network system is connected by the copper bar at the

secondary outlet end of the electric furnace transformer

6. Hydraulic system

The hydraulic system is composed of hydraulic pump device,

accumulator, control valve group and other components

7. Cooling water system

The cooling water system consists of pressure gauge, thermometer,

butterfly valve and water dispenser

8. Storage system and pneumatic conveying system

9. Iron ladle, slag device

The iron and slag are directly opened by plugging machine, and the

alloy is opened by hanging type.