| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Shaanxi Chengda |

| Model Number : | Complete equipment for refining furnace of chromium slag |

| Certification : | ISO9001 |

| Price : | Price and specifications can be agreed. |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 3set per month |

| Delivery Time : | 8-15work days |

Complete equipment for refining furnace of chromium slag

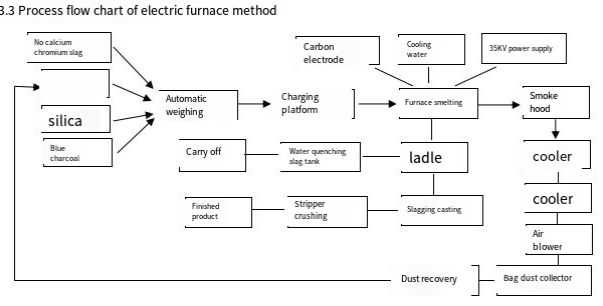

Technological process of production:

Description of the process:

The main raw materials of the special refining furnace are

calcium-free chromium slag, calcium-vanadium slag, carbonite and

silica, which are calculated according to the ingredients of raw

materials on site, accurately weighed by an electronic balance

according to a certain ratio, and reasonably batted and dried, and

then sent to the top silo of the 13.5-meter platform of the

electric furnace by a inclined bridge loading trolley. Through the

circular distribution system at the top of the electric furnace, it

is put into the top bin, and through the feeding pipe in the

furnace, it is continuously sent to the submerged arc melting. The

slag and hot metal are discharged through the iron outlet, injected

into the hot metal and slag bag, and some of the slag is removed by

water quenching method. After the oven is finished, the hot metal

package car is opened to the casting stage, after sedation, the

scum is lifted to the water quenching slag chute for slag

discharge, the remaining hot metal is poured into the ingot mold,

the alloy is slightly cooled and pry up, after natural cooling and

crushing, the crane is lifted to the iron box, and the cooling is

put into the storage.

The flue gas of the electric furnace enters the bag dust collector,

is treated, discharged after reaching the discharge standard, and

the dust dust is returned to the raw material workshop.

Structure type of equipment:

1) The use of fully water-cooled horizontal jacking hydraulic

cylinder pressure ring, so that the copper tile force uniform,

balanced and uniform conduction;

2) The use of new water-cooled cable technology and forged copper

shingles, water-cooled cable and copper pipe connection selection

of button-type connection, which can reduce the contact resistance;

3) The new short network structure of one to one between the

transformer outlet and the copper tile makes the equipment more

advanced and the operation rate is high;

4) The short-net design uses the three-phase electrode triangular

connection method, which has good short-net compensation, low

impedance, low three-phase unbalance coefficient, high power factor

and significant power-saving effect;

5) Adopt full hydraulic lock, PLC control, to achieve voltage

discharge, improve the operation rate of the electrode system;

6) The large current carrying conductor is made of non-magnetic

steel, which can greatly reduce the power loss;

7) The insulation system of the entire equipment is at least twice

insulated;

8) According to the smelting characteristics of special refining

furnaces, the automatic electrode regulator adopts the more mature

PLC+ proportional valve automatic regulation technology on steel

furnaces at present;

9) The furnace structure adopts a unique furnace form, which

greatly improves its reliability (lining life), and the power

saving effect is obvious.

Special refining furnaces using the new technology and equipment

are currently at the leading level in China.

Instruction of the equipment:

The main equipment adopts the semi-closed fixed furnace type with

low smoke hood. The design electrode adopts hydraulic cylinder

lifting device, short network adopts water-cooled cable,

water-cooled copper pipe, forged copper tile and so on.

The main equipment is composed of: furnace body, smoke hood and

flue, electrode part (including holder, electrode lifting device,

electrode pressure release device, hydraulic mechanical lock,

pressure ring device), eye opening machine system, hydraulic

system, etc.;

Auxiliary mechanical equipment: inclined bridge loading system,

factory circulating water cooling system, iron system, casting

equipment, etc.

Electrical equipment includes: high voltage power supply system,

electric furnace transformer, electric furnace control system.

|